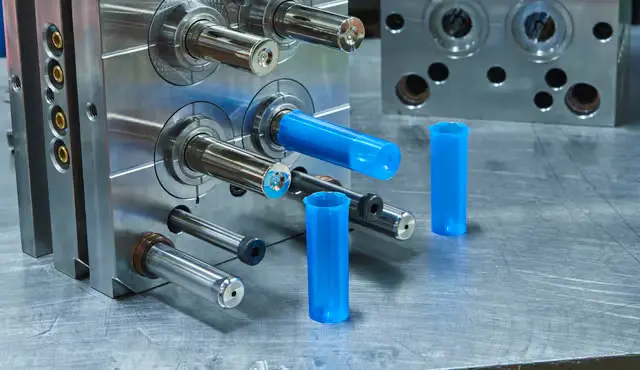

An important procedure in contemporary manufacturing is injection molding, which is necessary to efficiently produce complex, high-quality products. Leading China-based injection molding company HITOP is making great progress in this area. hitopindustrial.com, with its concentration on sophisticated mold design, quick prototyping, and precision molding, is a major participant in a number of industries, including the automotive, electronics, medical, and home appliance sectors. This article explores HITOP’s ideas, products, and the advantages they give to companies across the globe.

Overview of HITOP

Overview of the Company

HITOP is a well-known brand in the injection molding sector, renowned for its superb craftsmanship and creative ideas. The business produces high-performance molds and pieces by utilizing state-of-the-art technology and knowledge.

Global Reach and Website

HITOP’s English-language website*hitopindustrial.com*, caters to a global audience, showcasing their commitment to conducting business globally. The website offers detailed information on HITOP’s capabilities and services, making it an excellent resource for businesses searching for better manufacturing solutions.

Key Services Offered by HITOP

The Formation of Mold

Mold design service, the heart of HITOP’s production process, provides clients with the following advantages:

Advanced Technology –

CAD Software:Using the most latest Computer-Aided Design (CAD) tools, HITOP produces precise and efficient mold designs.

Innovative Techniques:Advanced design techniques ensure that molds meet exact specifications and performance requirements.

Personalized Solutions:Individualization Each mold is custom-made to fulfill the requirements of a certain project, whether it

Client-Partnership: HITOP collaborates closely with customers to comprehend their needs and provide customized solutions.

Quick Turnaround

A key component of HITOP’s service portfolio is rapid prototyping, which enables companies to:

Quicken Product Development

Swift Turnaround:HITOP offers quick prototype services to reduce development times and hasten time-to-market iterative Testing: Prototypes enable early testing and adjustments, improving the functionality and quality of the finished product.

Design Validation

Early Feedback:Quick prototypes make it easier to provide early criticism and make necessary revisions, guaranteeing that designs adhere to performance and quality requirements.

Reduced Risk:Costly errors during full-scale manufacturing are less likely to occur when validation is done early.

Molding via Injection

One essential service provided by HITOP is injection molding, which is distinguished by:

Accuracy and Effectiveness

High Accuracy:Complex items are produced with extreme precision and consistency thanks to HI TOPs injection molding method.

Advanced Machinery:Using cutting edge molding machinery improves output quality and productivity.

Material Expertise

Diverse Materials:To satisfy a range of client needs, HITOP works with a variety of materials, including metals and plastics.

Performance Optimization:The capacity to optimize durability and performance in finished goods is made possible by knowledge of material attributes.

Engineering Solutions and Innovations

Innovations in Manufacturing

HITOP continuously innovates to keep ahead of market trends, such as:

Technology Integration and Automation

Automated Systems:Including automation into the production process increases consistency and efficiency.

Technological Advancements:Using new technologies improves quality control and production capacity.

Enhanced Quality Control

Rigorous Testing:To make sure every mold satisfies exacting quality standards, HITOP uses extensive testing processes.

Continuous Improvement:Updating quality control procedures on a regular basis aids in maintaining high standards for the products.

Technical Resolutions

The engineering know-how of HITOP goes beyond conventional mold manufacturing:

Design Optimization

Manufacturability and utility:HITOP engineers strive to maximize designs for both manufacturability and utility.

Technical Expertise:Complex and high-performance mold creation is supported by extensive engineering knowledge.

Technical Support

Client advice:To help clients with any problems they might run across, HITOP offers technical support and advice.

Ongoing Assistance:Constant support makes sure that customers get the help they require all the way through the production process.

Applications Specific to Industry

Health Care Sector

The injection molding options offered by HITOP to the medical industry consist of:

High Precision Components –

Medical Devices:Manufacturing accurate and dependable components for use in medical equipment and devices

Regulatory Compliance:Ensuring that molds and products adhere to stringent regulations for the medical industry.

Quality Control

Durability and Reliability:Concentrate on producing resilient molds that can survive demanding use in medical settings.

Stringent requirements:Adherence to high-quality requirements to assure safety and effectiveness in medical applications.

The Electronics Sector

In the electronics industry, HITOP provides:

Complex and Sturdy Parts

Electronic Components:Production of complex and sturdy parts that are essential to electronic equipment.

High Performance:Guaranteeing the dependability and high performance of parts utilized in electronic applications.

Production Efficiency

Speed:Quick manufacturing cycles to keep up with the electronics industry’s rapid technical developments.

Precision:Precise molding to fulfill the precise requirements needed for electronic components.

Appliances for the Home

HITOP offers the following solutions for home appliances:

Sturdy and Functional Components

Appliance Parts:Manufacturing sturdy parts that guarantee long-term functionality for a range of home appliances;

Aesthetic Design:Capability to create components that are both functional and visually beautiful.

Economical Remedies

Cost Efficiency:Finding cost-effective solutions for home appliance makers by balancing quality and cost.

Scalability:The capacity to adjust output in accordance with project specifications and demand.

Aviation Sector

Regarding the aviation industry, HITOP provides:

Parts with High Performance

Aerospace Components:Producing parts with exceptional performance that adhere to strict safety and performance requirements.

Customization:Offering specialist aerospace applications customized solutions.

Safety and Compliance

Regulatory Standards:Ensuring adherence to safety requirements and industry rules pertaining to the aerospace sector.

Reliability:Concentrate on creating dependable parts that are necessary for the performance and safety of aircraft.

Automobile Sector

The automobile industry is served by HITOP with:

Accuracy and Quality

Automotive Parts:Manufacturing of accurate and superior parts essential to vehicle functionality and safety.

Advanced Materials:Improving automobile components through the use of advanced materials and manufacturing techniques.

Efficiency and Cost

The automobile industry needs high standards for efficiency in manufacturing.

Cost-Effective Solutions: Providing cost-effective solutions without sacrificing quality or performance.

HITOP’s Dedication to Quality

Assurance of Quality

HITOP is committed to upholding the highest levels of quality by using strict quality control and testing procedures.

Tailored Customer Support

The business places a high value on individualized service, collaborating closely with customers to fully comprehend their demands and provide customized solutions.

Ongoing Enhancement

In order to keep ahead of the competition, HITOP is dedicated to constant improvement and updates its technologies and procedures on a regular basis.

Concluding Remarks

HITOP’s dedication to quality, innovation, and individualized service sets it apart as a top injection molding manufacturer. With a wide range of services including injection molding, fast prototyping, and mold design, HITOP provides excellent manufacturing solutions to a number of sectors. HITOP is a dependable partner for companies in the medical, electronics, home appliances, aviation, and automotive sectors that need high-performance, long-lasting molds.